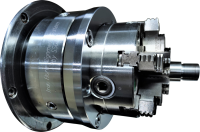

True Bore Alignment System!

V3 TBAS Now Shipping. lighter weight, Hard surface adjustment screws, Numbered adjustment Locations with 360 degree marks for indexing

I developed the True Bore Alignment System in 2011.

I wasn’t happy with the current action truing fixtures that were available on the market. I felt they put too much stress on the action during the truing process.

Although you could dial in an action to .0001 TIR. using a spider system, when adjustment screws were relieved and the action moved back to a stress-free state, the truing cuts were no longer true with the stress free action therefore possibly not even improving the action during the truing process. This encouraged me to press on with designing the True Bore Alignment System.

In 2011 I purchased my first Haas TL-1, this gave me the ability to machine the ball and socket into my fixture. After many design adjustments and many long hours the True Bore Alignment System was created. It was a success from the start! It made my job in the shop so much easier! Quick dial in time, near stress-free work holding, maintaining .0001 TIR through machining processes, allowing me to hold short barrels and long barrels while bringing two points of the bore into alignment. All things that contribute to a superior accurate rifle!

Up until March of 2021 the True Bore Alignment System has seen almost no design changes, but in March of 2021 I decided to update the radial cast front plate, primarily due to the castings that I purchase from a manufacturer having an 8 month lead time and my product supply being almost gone. I decided to use this opportunity to improve rigidity as well as aesthetics and that brings us up to date.

I have over 250 of these in service at some of the biggest named manufacturers in the industry as well as many accuracy minded sole proprietors and hobbyists and I am excited to serve many more of you with my innovative precision work holding and rifle building solutions. The True Bore Alignment system was engineered and has always been manufactured here at Straight Shot Gunsmithing.

A barrel or receiver is held in the chuck and all the adjustments are made for axial and radial alignment on the True Bore Alignment System, therefore the stress that is incurred during adjustments is only effecting the True Bore Alignment System and not the part that is being held.

The True Bore Alignment System works extremely well for holding barrels, receivers, bolts etc...

Why should I purchase the True Bore Alignment System?

● Versatility in holding receivers, barrels, bolts Etc... when machining

● Increased productivity

● Better surface finishes due to rigid holding

● Holding barrels too short to go through the spindle while still having the ability to dial the bore in two points

● Holding parts stress free

● Extreme precision machining

● Eliminating chucking error

Click Here T.B.A.S. Instruction Manual

True Bore Alignment System

you can also order by mail with check or money order

Send orders to

2175 41st Ave SW

Center ND 58530

Initial TBAS set up instruction video